Conveyor belt connecting – choose the appropriate method for your needs!

In industry where materials are transported on conveyor belts, the key issue is to create durable and reliable connections between belt segments. In this article, the term conveyor belt is used interchangeably for a conveyor belt. There are several proven methods of joining conveyor belts, each with its own unique characteristics and appropriate use. In this article, we will introduce four common methods: vulcanization, mechanical bonding, steel fittings and bonding.

Conveyor belt connecting – Vulcanization

Vulcanization is one of the most reliable and durable methods of joining transmission belts made of rubber or rubberized materials. The vulcanization process involves joining the two ends of the belt by applying high temperature and pressure to create a permanent chemical bond. Vulcanization requires the use of specialized tools and vulcanization materials, such as adhesives and rubber mats. This method is especially effective for belts that will be subjected to harsh conditions such as high loads, exposure to high temperatures or contact with chemicals.

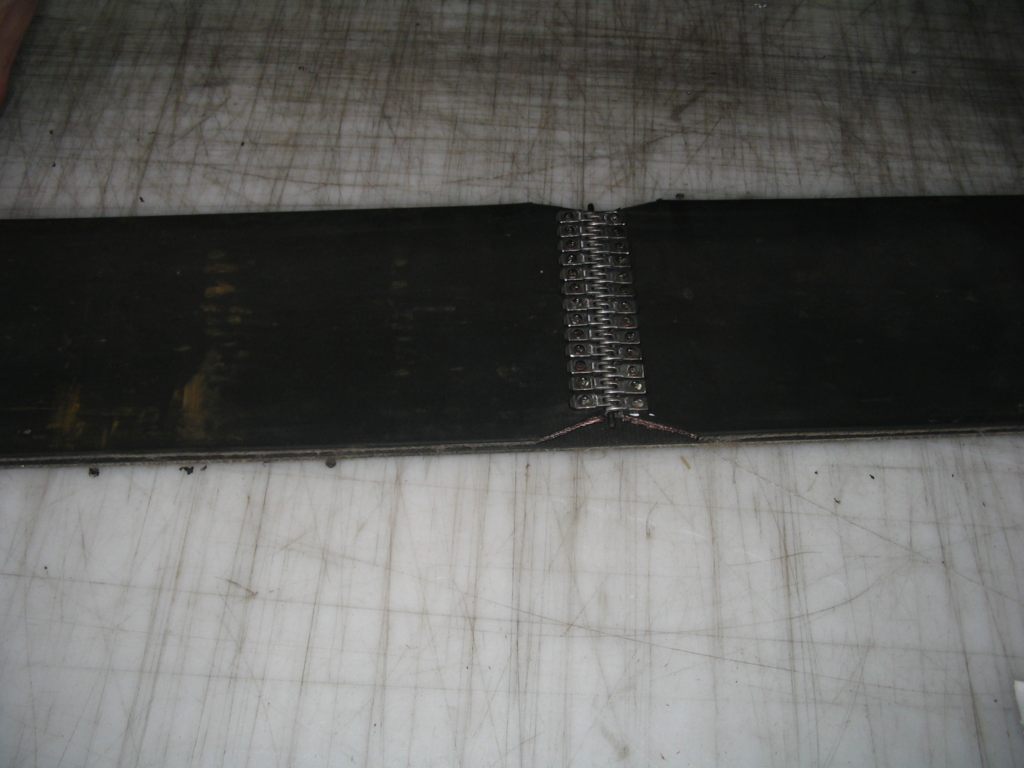

Conveyor belt connecting – Mechanical connection

Mechanical splicing of conveyor belts is popular due to its simplicity and speed. This method involves the use of special buckles, screws, hooks or snaps to connect the two ends of the tape. These elements are placed along the edge of the tape and then clamped, creating a permanent connection. Mechanical splicing is often used for belts made of fabric or other flexible materials that are not suitable for welding or vulcanization. It is also useful when replacing a damaged belt section as the mechanical link can be easily removed and replaced.

Steel fittings

In the case of heavy conveyor belts, we use steel connectors to create durable connections. Steel connectors consist of metal plates that are attached to the ends of the belt with fastening screws. This type of connection provides high strength and stability. This is essential when transporting heavy materials or in difficult working conditions. Installation of steel connectors requires a specialized tool and skills, but the connection is strong and durable. This minimizes the risk of damaging the belt and disrupting the material handling process.

Gluing

Bonding is another popular method of joining conveyor belts, especially for belts made of rubber or fabric materials. The gluing process involves the use of special adhesives or binders at the ends of the tape and their precise connection to each other. Gluing is carried out in accordance with the recommendations of the adhesive manufacturer and may require appropriate surface preparation of the tape. This method can be used when other techniques such as welding or mechanical joining are not possible or appropriate. Bonding provides a flexible connection that resists tensile and compressive forces.

Conveyor belt connecting – summary

There are many factors to consider when selecting the appropriate belt splicing method. These are: type of belt, its material, working environment, load on the belt and requirements for the strength and durability of the connection. Each of the above methods has its advantages and limitations. It is important to consult with professionals, a conveyor belt manufacturer or a maintenance specialist, to select the optimal splicing method for your specific conditions and needs.

Remember that a well-made connection of conveyor belts is crucial to the efficiency and reliability of the material handling process. Therefore, it is worth taking the time and attention to carefully consider and apply the correct bonding method. Ensure smooth and effective operation of conveyor belts in your plant – contact the Center for Belts and Belts .