Anker connection system

Wire hooks

Connected hooks

Belt splicing

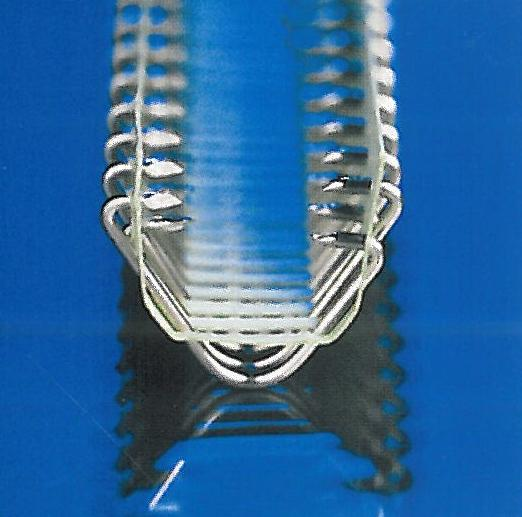

Wire hooks

For use in conveyor belts used with low loads.

Anker connection systems are a response to the requirements posed by the diverse constructions of tapes and materials from which they are made, as well as the variety of applied coatings in combination with a wide spectrum of tape widths and thicknesses.

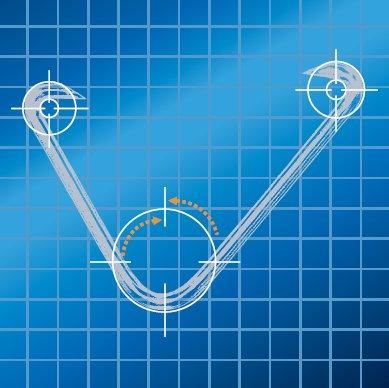

Optimal shape of Anker connection

Each type, and in each type also the single connection, is specifically designed to meet the highest demands. The key features of the optimized geometry are:

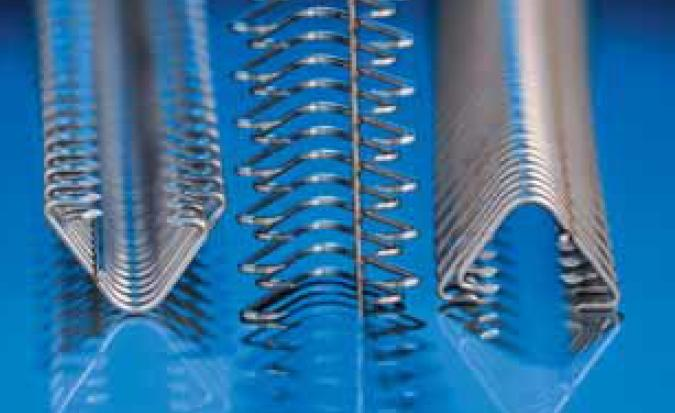

Double rolled wire and horizontally cut tips

The double rolling of the wire used in Anker connection joints provides increased gripping ability and lateral stability combined with a very flat and even joint area.

The particularly complex production process of the horizontally cut tips ensures perfect anchoring of the connection in the belt. Whereas classically cut points tend to bend sideways, horizontally cut points are specially designed so that the points of the hooks bend perfectly parallel to the edge of the tape.

4-level tip arrangement (G series)

The design of the tips arranged in four levels has been patented worldwide. This solution increases the tear and fracture strength of the extremely flat and abrasion-resistant G-series joints by 50%.

Wire hooks bonded with paper

Designed for use with a wide range of tapes and a wide range of thicknesses up to 10mm.

Hook types

Type #25

Technical Specifications:

Type #30

Technical Specifications:

Type #35

Technical Specifications:

Type #40

Technical Specifications:

AP Type

Technical Specifications:

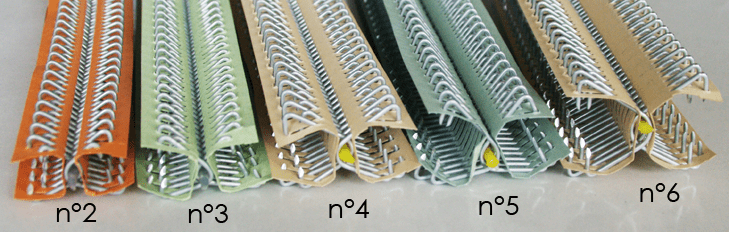

Types #2 - #6

The most important advantages:

Technical Specifications:

| Hooks | Type #2 | Type #3 | Type #4 | Type #5 | Type #6 |

| Tape thickness, mm | 1 – 4 | 3 – 4 | 5 – 6 | 6 – 8.5 | 8.5 – 10 |

| belt strength, N/mm | 20 | 25 | thirty | 40 | 45 |

| Min. roll Ø, mm | 50 | 75 | 100 | 125 | 150 |

| hook wire Ø, mm | 1.2 | 1.38 | |||

| Stroke, mm | 3.67 | ||||

The standard pack contains 12 rows of x 300mm paper hooks, together with a nylon bar. It is also possible to deliver poles made of steel (up to 30 m in one piece). Hooks are available in galvanized steel or AISI 430 stainless steel.

| Rod | Ø, mm |

| stainless steel rod | 1.0 |

| 1.5 | |

| 1.8 | |

| 2.5 | |

| stainless steel bar with PA coating | 1.5 |

| 2.0 | |

| 3.0 | |

| stainless steel rope in PA coating | 1.5 |

| 2.2 | |

| 2.6 | |

| 3.6 |

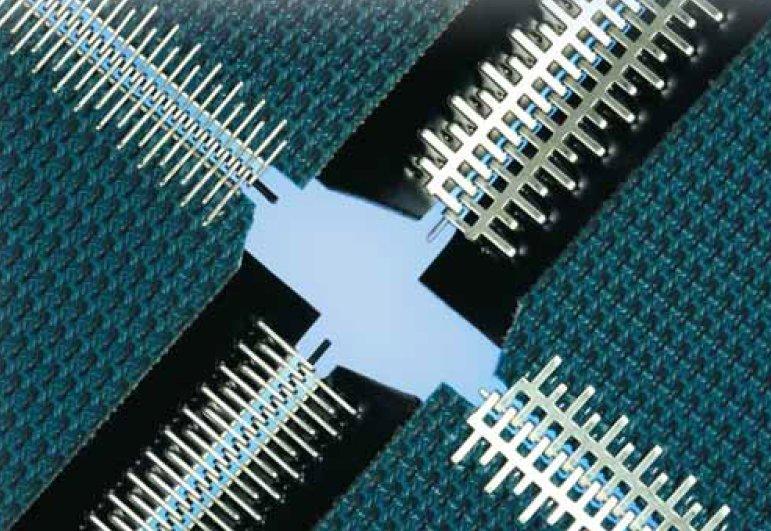

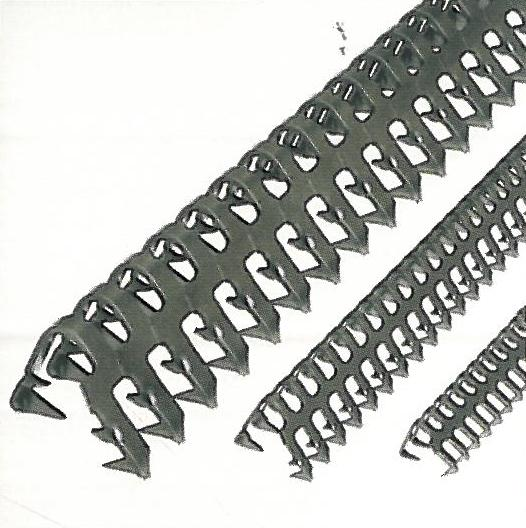

Connected hooks

It is a connection made of hooks joined with a transverse wire.

Used successfully for over 50 years in conveyor and conveyor belts.

The cross wire stabilizes the connection and prevents loosening of individual hooks.

Specially designed for belts used in agriculture, food industry and logistics.

Connected hook types

Type A30

Technical Specifications:

Type A34

Specially designed for feeders and bending machines in laundries.

Technical Specifications:

Type A35

Technical Specifications:

Type A36

Technical Specifications:

Type A40

Technical Specifications:

Types A2 - A7

Technical Specifications:

Types G00 - G06

Technical Specifications:

Anker connection conveyor belt splicing

For more informations about available product visit www.c-t-p.pl