Depending on the belt type, operating conditions, conveyor parameters and user requirements, it is possible to use various types of conveyor belts connections. In general, connections can be divided into:

Conveyors equipped with cleaning scrapers usually force the use of vulcanized joints, which are perfectly smooth and do not cause faster wear of the cleaning elements and eliminate the risk of damage to the joint by the scraper. Making this type of joint requires the use of a specialized vulcanizing press and vulcanizing materials. It should be performed by a specialized service team.

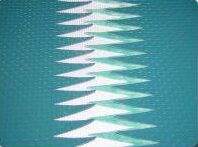

There are many types of mechanical connections. From the simplest, characterized by easy assembly that does not require the use of specialized assembly equipment, to specialized connectors that are an alternative to vulcanization. A mechanical connection, for proper installation, usually requires the use of a mounting strip designed for a specific type of connection. An interesting mechanical connection is the fabric-rubber Super-Screw connection. It is characterized by easy and quick assembly, does not require the use of mounting strips, can cooperate with cleaning scrapers, is tight and achieves strength and durability comparable to vulcanization.

Bonding of conveyor belts using the so-called when cold, it keeps the tape tight, the joint can work with cleaning scrapers. It should be performed by a specialist. The time it takes for the adhesive to develop its full strength is typically 24 hours.

Tape and Belt Center has the appropriate equipment and qualified staff to perform each of the above-mentioned types of connections. The offer also includes various types of mechanical connectors and mounting strips.

Vulcanized

"Double tooth" connection

"Tab" connection

Iklumet straps for sewing tapes

Rubber belts

Rubber belts are vulcanized using the overlapping method.

The number of steps and their length depends on the belt type. In the same way, rubber bands for cold glueing are prepared.

Mechanical

Iklumet, PU, mechanical PVC connection

Steel mechanical couplings

Hidden mechanical connections