Cold gluing of conveyor belts – introduction

Cold gluing of conveyor belts is one of the techniques used in the repair and maintenance of conveyor belts. To ensure safe transport of materials, it is important that all conveyor components are solidly made and precisely glued. Cold bonding is one of the most important ways to join belts, enabling them to withstand the high longitudinal forces they are subjected to. This technique has many advantages and is applicable in various situations.

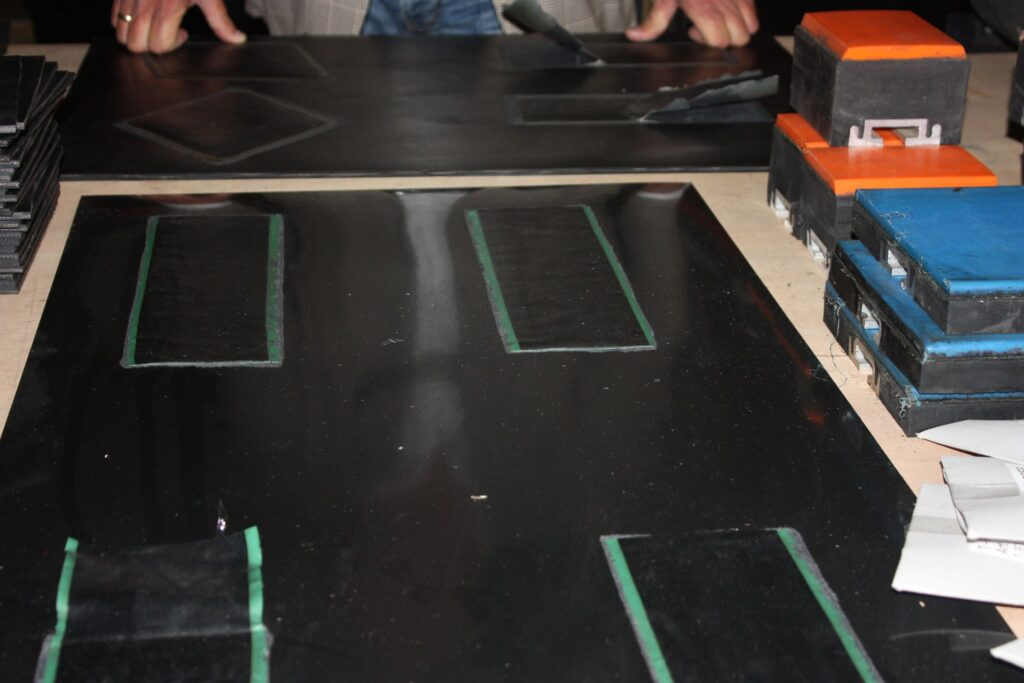

Cold gluing is especially useful for small tapes up to 100 centimeters wide. It is also popular for tapes placed in hard-to-reach places. This method is used for staggered joints and several spacers. Thanks to cold gluing, you can fill any gaps, close joints or connect individual elements of the tape. This is especially useful when traditional bonding methods such as vulcanization are inconvenient or time consuming.

Cold gluing of conveyor belts – how is it going?

Cold gluing of tapes requires the use of a special quick-drying adhesive. These adhesives are safe to use and are characterized by high strength. The quick drying of the adhesive allows for repairs to be carried out in a short time, which is important in the event of unforeseen failures of the conveyor belt. Depending on the specific case and the glue used for cold bonding, the use of additional components, such as a rubber plate, may also be required to ensure a permanent and strong bond.

Advantages of cold gluing conveyor belts

Cold gluing tapes has many advantages. First, it is a quick belt repair method that minimizes machine downtime and speeds up the resumption of the material handling process. Secondly, cold bonding is effective at repairing gaps and damage to the belt, extending its life and avoiding the need to replace the entire belt. In addition, cold bonding is used for various types of conveyor belts, which makes this method versatile.

Good to know

However, it should be remembered that cold bonding is not a universal method and there are some limitations. Not all conveyor belts are repaired with this technique, so our experts always provide expert advice and assess whether cold bonding is appropriate for the belt. In case of doubt, you can always consult our team who will help you choose the right repair solution for your conveyor belts.

Summary

In conclusion, cold bonding of belts is an effective method of repairing conveyor belts. It is a fast, durable and durable solution that allows you to maintain the continuity of the material transport process. Thanks to this technique, it is possible to reduce the costs of belt replacement and extend their life.

If you need more information about – contact us!